Our Industrial Maintenance Technology (IMT) group provides a comprehensive list of maintenance and repair services including vibration analysis, lubrication, and laser alignment. Our Solution: If you’re currently experiencing these issues, IBT can help.

REASON FOR MOTOR WINDING BURN INSTALL

Or, install a motor designed with proper insulation for operation at higher ambient temperatures.

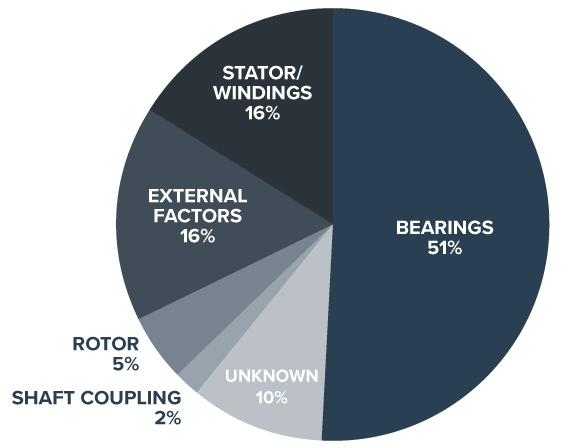

IBT’s Electrical Group Director, Joe Purcell, recommends avoiding motor use if the voltage imbalance is greater than 5 percent. For instance, a three percent voltage imbalance can cause an 18 percent temperature rise in the motor.įor proper motor operation, phase voltage imbalance should be less than one percent. Electrical SupplyĪ voltage imbalance can result in a motor to overheat. To help avoid this problem, most electric motor manufacturers specify the maximum number, or frequency, of starts for a given motor type. Short cycling can occur if the motor is repeatedly turned off and on before it has the chance to cool down. An overload often occurs when the motor provides more power than what it was rated for. If your motor is drawing excessive current, showing signs of insufficient torque, or overheating, chances are it’s overloaded. industrial and commercial sectors? It’s hardly surprising when you think about it - most operations run on some type of motor whether it’s a drive fan, pump, compressor, saw, crusher, or conveyor.Īs an essential part to many applications, it’s important to regularly take preventive measures to avoid these four common causes of motor failure: 1. If it does not change with the change of the power supply, the one-phase winding of the larger current will be short-circuited.Did you know that motor-driven equipment accounts for 64 percent of the electricity consumed in the U.S. In no-load operation of the motor, the three-phase current is measured first, and then the two-phase current is measured and compared. A group of short circuit faults with low voltage are detected.

REASON FOR MOTOR WINDING BURN SERIES

Three windings are connected in series and connected to low voltage safe alternating current. Measuring the insulation resistance between any two-phase windings, if the reading is minimal or zero, shows that there is a short circuit between the two-phase windings. If the difference exceeds, there will be short circuit fault in the phase with small resistance. When measuring the DC resistance of each winding, the difference should not exceed 5%. Measured by ammeter, if the current of a phase is too large, it indicates that there is a short circuit in the phase. Running without load for 20 minutes (stop immediately when abnormal is found), touch each part of the winding with the back of your hand to check if it exceeds normal temperature.

After the winding is overheated, it leaves dark brown and has a peculiar smell. Observe whether the junction box and winding end are burnt or not. (7) Metal foreign materials fall into the motor and oil stain is excessive. (6) Insulation damage caused by rotor sweeping heat. (5) Insulation damage is caused by friction between rotor and stator winding ends. (4) Insulation breakdown due to overvoltage or lightning strike. (3) The damp winding reduces the insulation resistance and causes insulation breakdown. (2) Insulation damage caused by wire insertion. (1) The long-term overload of the motor causes aging of the insulation. Reasons for Short Circuit Faults of Motor Windings

0 kommentar(er)

0 kommentar(er)